Infra

Precast Structures

What Is an Anchor Cone?

Specifications

- Material: High-quality hot-rolled steel

- Shape: Compact

- Pressure Bearing Capacity: Maximum 1230 MPa

- Ideal for: Bridge construction applications

- Yield Strength: Up to 1080 MPa

- Surface: Galvanized or electroplated for rust and wear resistance

- Manufacturing Technology: Advanced forging or casting

- Design: Standard threading

- Strength: High tensile strength

- Durability: Long-lasting

- Available in: Standard and custom-made specifications

Available Sizes of Anchor Cones

The size of an anchor cone depends on the size and type of the prestressing strand it is designed to hold. At Jalpa Devi Engineering Pvt. Ltd., we manufacture anchor cones in the following common sizes:

12.7 mm

15.2 mm

15.7 mm

17.8 mm

18 mm

21.6 mm

Specifications of Anchor Cones

- Anchor Cone 1906

- Anchor Cone 1905 & 1206

- Anchor Cone 1205

- Anchor Cone 2206

- Anchor Cone 0506

Our expertise in manufacturing diverse sizes of anchor cones and cone mantles for bridge construction makes us a reputed anchor cone manufacturer based in Indore, supplying products all over India. We offer anchor cones in both round flange and square flange designs and can also manufacture customized designs to cater to specific project needs.

Choose Jalpa Devi Engineering Pvt. Ltd. for high-quality, reliable anchor cones tailored to your construction needs.

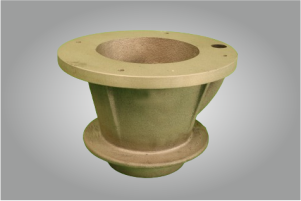

n anchor cone is a critical component used to secure the end of a prestressing strand or LRPC strand within a concrete structure. Typically made of steel, the anchor cone is inserted into a drilled hole in the concrete to provide a secure and stable connection.

Developed using high-quality hot rolled steel, this compact-shaped anchor cone boasts a maximum pressure bearing capacity of 1230 MPa, making it ideal for bridge construction applications. With a yield strength of up to 1080 MPa, this anchor cone ensures robust performance and durability. Its galvanized or electroplated surface provides excellent resistance to rust and wear.

Manufactured using advanced forging or casting technology, this anchor cone features a standard threading design, high tensile strength, and long-lasting quality. We offer this product in both standard and custom-made specifications to meet diverse project requirements.

Nationwide Supply

We supply anchor cones across India, including but not limited to:

- Andhra Pradesh

- Manipur

- Arunachal Pradesh

- Himachal Pradesh

- Madhya Pradesh

- Meghalaya

- Nagaland

- Sikkim

- Uttar Pradesh

Choose Jalpa Devi Engineering Pvt. Ltd. for high-quality, reliable anchor cones tailored to your construction needs.

Bridge Bearings

ISO Compliance

Materials

High-Quality Steel: Known for its strength and resilience, suitable for critical structural applications.

Brass: Used for internal sealing rings, offering excellent durability and resistance to wear.

PTFE (Polytetrafluoroethylene): A low-friction material used in bearing interfaces, ensuring smooth movement and reducing wear.

Features

Our bearing components are designed to deliver superior performance in various structural applications. Key features include:

- Strong Rust Resistance: All metallic parts are protected against corrosion through advanced galvanization and epoxy painting processes, ensuring longevity even in harsh environments.

- Weather Resistance: Our components are designed to withstand extreme weather conditions, maintaining their structural integrity and performance in diverse climates.

- High Load Capacity: Capable of handling significant loads, ensuring robust support for bridge and structural applications.

- Advanced Manufacturing Techniques: Utilizing state-of-the-art forging and casting technologies to produce components with precise dimensions and excellent mechanical properties.

- Low Friction Coefficient: The use of PTFE in bearing interfaces provides a low friction coefficient (between 1% and 3%), allowing for smooth movement and reducing operational wear.

- Ease of Installation and Maintenance: Designed for quick and easy installation, our components also facilitate straightforward maintenance and replacement, minimizing downtime.

- Customized Solutions: We offer both standard and custom-made specifications to meet the unique requirements of different projects, ensuring optimal performance and compatibility.

Product Range

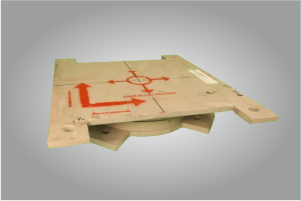

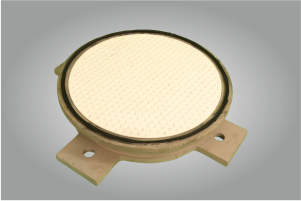

- Top Plate for Pot Bearing: Designed to accommodate sliding movements and distribute loads effectively.

- Piston for Pot Bearing: Protects the elastomer pad and enhances durability.

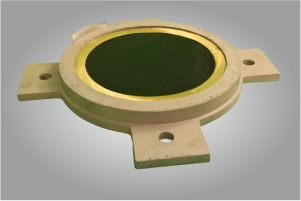

- Pot/Cylinder for Pot Bearing: Withstands vertical and horizontal loads, allowing controlled movement and rotation.

- Top Plate for Spherical Bearing: Accommodates rotational movements, ensuring smooth load transfer.

- Pot/Cylinder for Spherical Bearing: Handles complex load conditions, offering high durability and performance.

Choose Jalpa Devi Engineering Pvt Ltd for ISO-compliant, high-performance bearing components made from top-quality materials. Contact us today to learn more about our products and how we can support your structural engineering needs.