Irrigation/Dam

Irrigation/Dam

At Jalpa Devi Engineering Pvt Ltd (JDEPL), we specialize in the manufacturing of high-quality components essential for irrigation and dam projects. Our range of products includes robust rope drums, precision-engineered drum gears, second gears, pulley OD, C.T. wheels, C.T. gear wheels, L.T. wheels, and rim gears. Each of these components is meticulously crafted using premium-grade materials such as carbon steel to ensure durability, strength, and reliable performance under demanding conditions. These products are integral to the smooth operation of heavy-duty machinery used in irrigation systems and dam constructions, where they play crucial roles in facilitating efficient water management and structural stability.

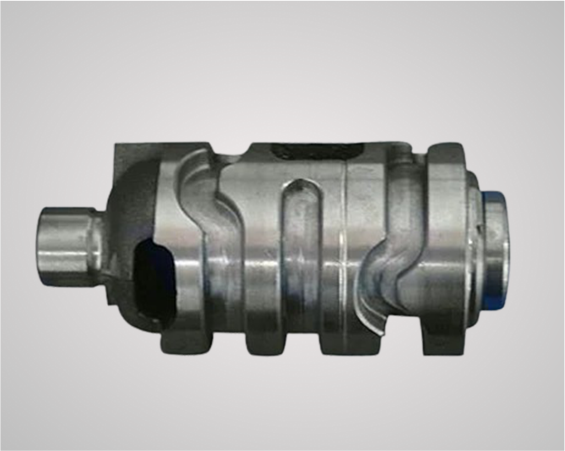

Application of Rope Drum

- Utilized in crane components for winding hoisting ropes, particularly in double girder cranes.

- Typically made of cast iron; can also be constructed from steel casting or rolled steel welded when required.

- Integral part of large tonnage hoisting machinery, providing high-performance capabilities.

- Comprises drum, gearwheel, shaft, hub, bearing, and bearing body.

Features of Rope Drum

- Precision manufacturing ensures quality and reliability.

- High hardness, excellent toughness, sturdy, and durable construction.

- Simple structure for ease of use and maintenance.

- Large capacity suitable for heavy-duty lifting operations.

- Easy operation, facilitating efficient crane handling.

- Simple maintenance procedures for prolonged service life.

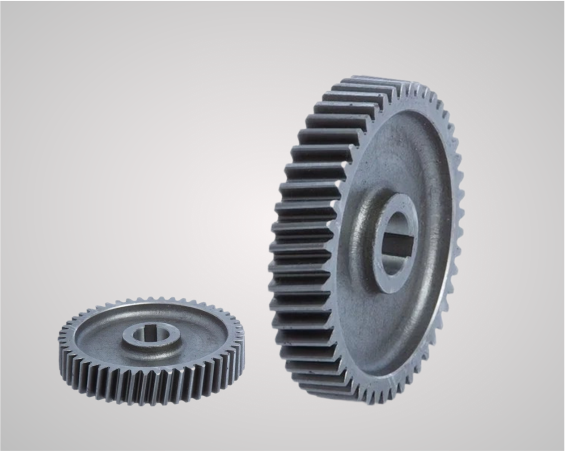

Drum Gear

We specialize in metal casting processes to craft world-class quality Carbon Steel Drum Gears, meticulously manufactured to meet industrial standards. Our Drum Gears are renowned for their durability, resistance, and adherence to industry specifications. Made from high-quality carbon steel, these gears are designed for optimal performance and are essential components in various applications where precision and reliability are paramount. The manufacturing process adheres to strict quality controls, guaranteeing each gear’s reliability and longevity, ensuring they meet the rigorous demands of industrial use.

Our casting process ensures the highest standards of quality and performance, providing robust and reliable components that withstand rigorous operational conditions.

Second Gear

Equipped with a state-of-the-art infrastructure, we are a leading manufacturer of a diverse range of second Gears. These gears are produced using high-quality raw materials and advanced technology, ensuring compliance with industry standards. To meet the varied needs of our clients, we offer customization options for these gears in different sizes and designs. Our second Gears are widely used across various industries, including manufacturing and construction.

Pully OD

We specialize in the casting of Pulley OD-820 MM-P274, made from high-quality Carbon Steel GR230-450N. This pulley is engineered to deliver exceptional performance and reliability in demanding industrial environments. Our Pulley OD-820 MM-P274 is an ideal choice for industries that require robust and reliable components to maintain operational efficiency and productivity.

C.T. Wheel, OD

C.T. wheels play a crucial role in various industrial equipment, including cranes, conveyors, hoists, and other machinery. They serve as integral components that facilitate smooth movement and efficient operation. However, due to the constant friction between C.T. wheels and rails, they are susceptible to wear and tear over time.

As a leading manufacturer in the market, we specialize in producing high-quality CT Wheels. Our long travel wheels are straight threaded double flange forged steel wheels. These wheels are supported on anti-friction ball or double row self-aligned spherical roller bearings, housed in special blocks of ‘L’ type design (‘L’ type bearings) for easy maintenance.

These crane wheels are exceptionally durable and are well-suited for applications involving flange loading. Furthermore, they are easy to install, resistant to corrosion, and have a longer usage life, making them ideal for industrial applications where reliability and longevity are Fundamental.

L.T. Wheel, Od

We have a wealth of experience in manufacturing L.T. Wheels in Madhya Pradesh. Our L.T. Wheels are meticulously designed by experienced professionals, utilizing optimum quality raw materials and modern methodologies to ensure exceptional performance and durability.

Castings for L.T. Wheels

Our L.T. Wheels are engineered to deliver long-lasting performance across a diverse range of industrial applications. The use of high-grade Carbon Steel GR280-520N ensures durability and strength, making these wheels suitable for heavy-duty use. Their versatility allows them to be utilized in various industries, providing efficient and reliable operation. Whether in manufacturing, construction, or other industrial settings, our L.T. Wheels are designed to meet your specific needs and deliver superior performance.

Features:

Diameter: 760mm

Material: Carbon Steel GR280-520N

Performance: Long-lasting and reliable performance

Versatility: Wide range of applications

Rim Gear, OD

Our Rim Gears are engineered to provide optimal performance, high durability, and excellent corrosion resistance. Tailored for industrial applications that demand reliable gear solutions, our Rim Gears excel in delivering long-lasting and efficient operation.

Our L.T. Wheels are engineered to deliver long-lasting performance across a diverse range of industrial applications. The use of high-grade Carbon Steel GR280-520N ensures durability and strength, making these wheels suitable for heavy-duty use. Their versatility allows them to be utilized in various industries, providing efficient and reliable operation. Whether in manufacturing, construction, or other industrial settings, our L.T. Wheels are designed to meet your specific needs and deliver superior performance.