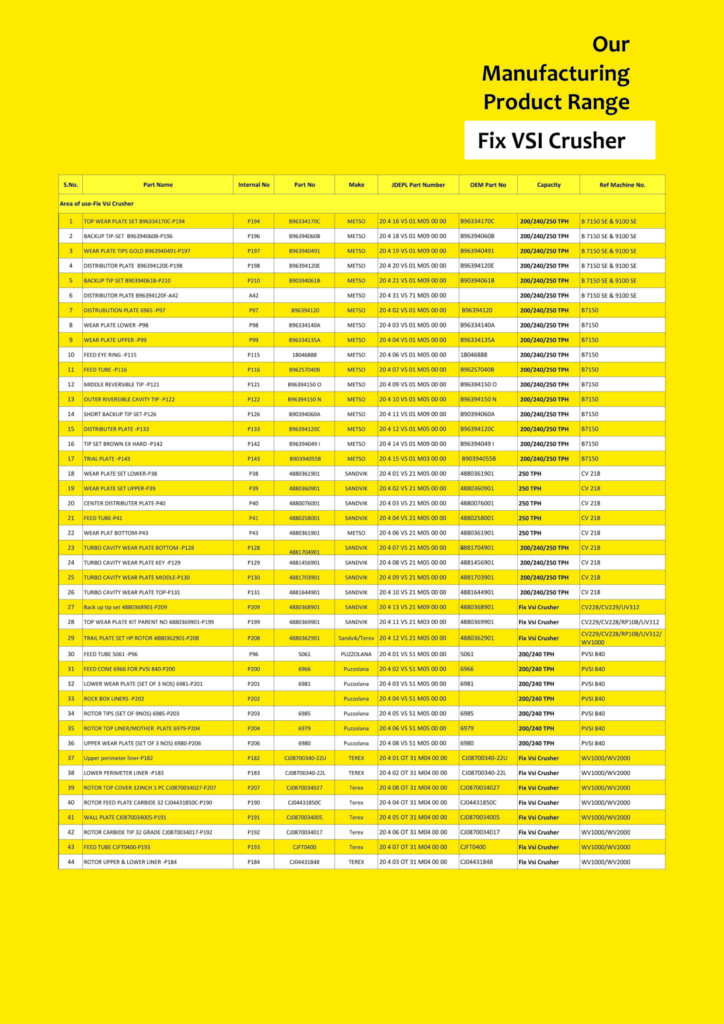

Vertical Shaft Impact Crushers

Vertical Shaft Impact

Vertical shaft compound crushers are screenless, adjustable fine crushing machines, optimized and introduced by our company to absorb advanced fine crushing technology both domestically and internationally. They incorporate rock-on-rock crushing technology that has revolutionized the aggregates and mineral industries worldwide. These crushers are designed for low service requirements, with easy lubrication and the assurance of continuous operation. They are suitable for fine crushing of medium-hardness materials such as dolomite, coke gemstone, lead-zinc ore, serpentine, blast furnace slag, coal gangue, phosphate rock, and more. They are particularly effective for crushing hard limestone, dolomite, minerals, basalt, etc., making them ideal for artificial sand making and highway pavement aggregate production.