Fabrication

Fabrication

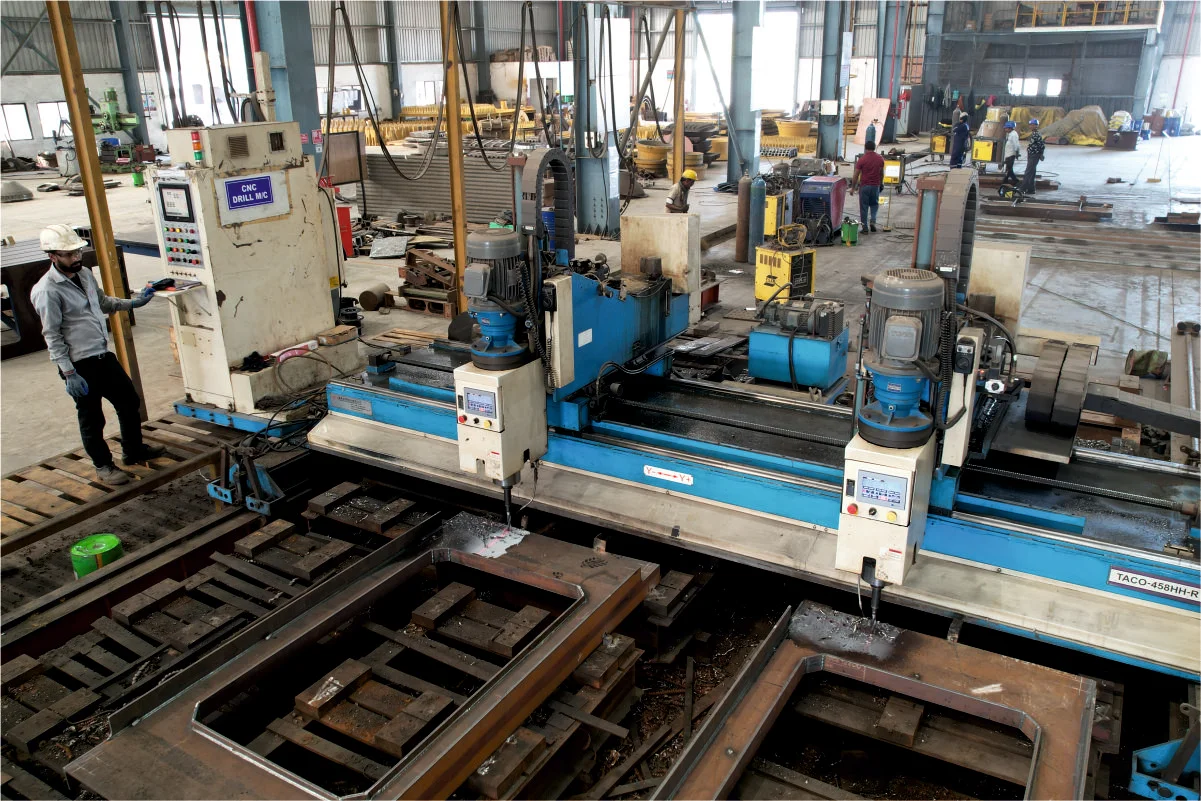

At Jalpa Devi Engineering, our fabrication equipment is precisely developed to suit the ever-increasing need for innovative and unique constructions. We seek to create exceptional technical solutions by merging cutting-edge technology with modernistic and functional designs. We manufacture steel superstructures for cable stays, suspension, and extra-dose bridges weighing up to 150MT per structure.

USPs

- Advanced 3D designing, modeling, and simulation software: By making use of cutting-edge 3D modeling, design, and simulation technologies, we improve product optimization and visualization, guaranteeing improved product quality.

- Robotic cutting and welding lines: Our fabrication plant uses robotic cutting and welding lines for optimal weld quality and to guarantee the durability and strength of our constructions.

- CNC drilling and laser sensing: CNC drilling machines equipped with laser sensing technology provide precise drilling, making certain all components fit accurately within the greater structure.

- Automatic beam and girder welding line: We can precisely weld and straighten large-scale constructions using our state-of-the-art automated beam and girder welding line, capable of handling girders as tall as 2.5 meters.

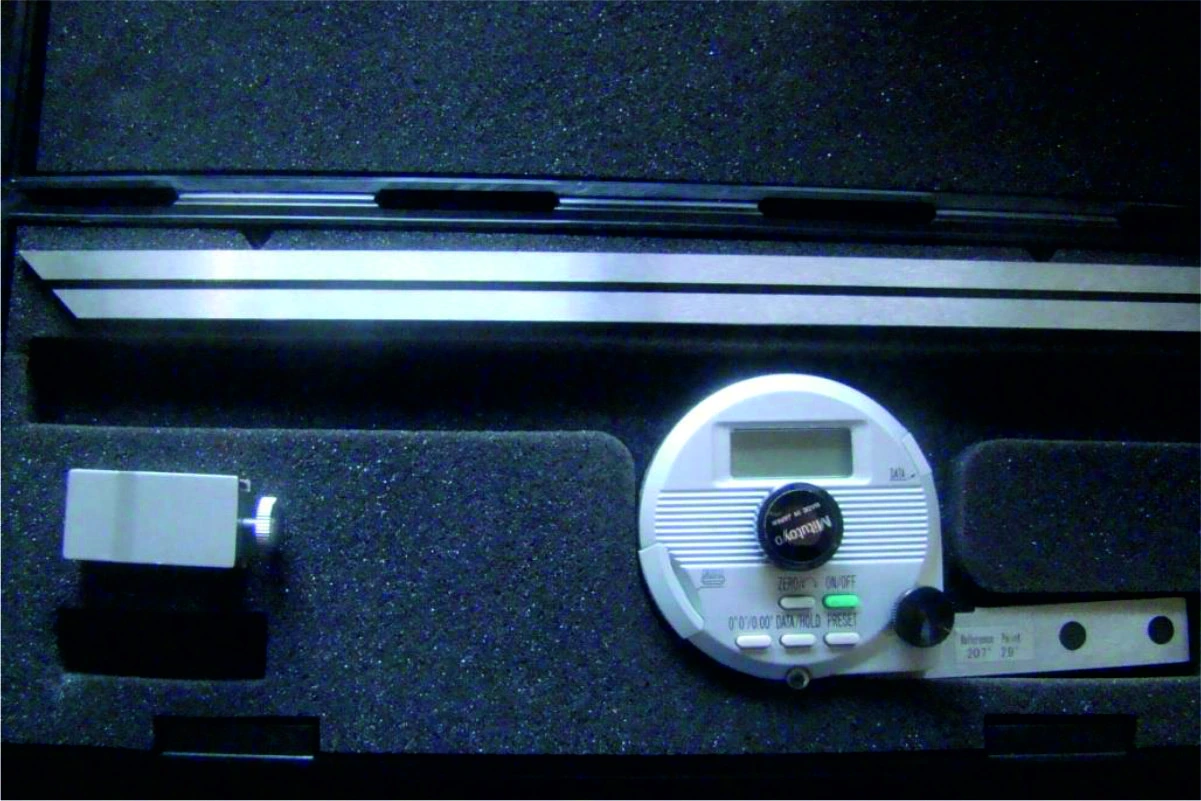

- Controlled torquing: Our fabricated structures are torqued appropriately within 5% of the torque value, assuring secure joints and connections for strength and stability under challenging conditions.