Jaw Plates

Jaw Plates

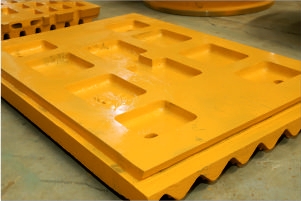

The jaw plate is a crucial part of the jaw crusher machine, designed to crush materials such as granite, iron ore, stone, trap rock, and coal. It delivers efficient performance and high crushing output. With its rugged construction, energy-efficient operation, and low maintenance needs, the jaw plate ensures the reliable functioning of the jaw crusher. Manufactured and supplied by Model Steel Casting, the jaw crusher machine features exceptional strength, a breakage-free finish, and sturdy construction. Also known as the tooth plate, this component is indispensable for the jaw crusher’s resistance and longevity.

Hi-Manganese Steel Jaw Plate

Jaw crusher plates made from high manganese steel are developed using the latest casting technology. These plates are extensively used in the chemical, construction, metallurgy, and mining industries. They are noted for their standard density, precise dimensions, and smooth surface. Renowned for their wear resistance and long lifespan, these jaw crusher plates undergo CO2 welding technology and annealing processes to enhance their strength. Their quality is evaluated based on diameter, design precision, durability, surface finish, strength, and resistance properties. With effective corrosion protection, these jaw crusher components ensure reliable performance for many years.

Although high chromium cast iron is highly resistant to wear, it lacks toughness. When exposed to impact or compression, it often fractures or peels off after minimal deformation. Hence, using high chromium cast iron alone for jaw plates may not yield optimal results. Composite jaw plates, including Mn13Cr2 and Mn18Cr2, are made of high manganese steel embedded in or bonded to high chromium cast iron, and have gained popularity in recent years. This combination leverages the wear resistance of high chromium cast iron and the toughness of high manganese steel, significantly enhancing the jaw plate’s lifespan.

Applicable Equipment

Jaw Crusher

Composite jaw plates are designed for use in jaw crushers. These jaw plates are specifically engineered to enhance the performance and longevity of jaw crushers by providing superior wear resistance and toughness. They are ideal for crushing operations where materials are subjected to high impact and compression forces. By using composite jaw plates, the efficiency of the jaw crusher is significantly improved, resulting in reduced downtime and maintenance costs.

Features:

- Corrosion Resistance

- Longer Life

- Accurate Dimensions

- Impact Proof

- High Strength

- Simple Installation

- High Durability